Maurice Dickens

Morris Minor Series II 1952-1956

In 1952, the Minor line was updated with an Austin-designed 803 cc (49.0 cu in) overhead valve A-series engine, replacing the original side-valve unit. The engine had been designed for the Minor's main competition, the Austin A30, but became available as Austin and Morris were merged into the British Motor Corporation. The new engine felt stronger, though all measurements were smaller than the old. The 52 second drive to 60 mph (97 km/h) was still calm, with 63 mph (101 km/h) as the top speed. Fuel consumption also rose to 36 miles per imperial gallon (7.8 L/100 km; 30 mpg‑US). It was this model that took part in the famous road test carried out by the Experimental Department of the Nuffield Organisation. A production Minor covered a year’s worth of motoring (10,000 miles) in just 10 days! The test was carried out at Goodwood road circuit and a team of six drivers put the car through its paces non stop for the duration. The Minor was driven an average of 45mph and returned an average of 43mpg. There were some slight alterations to the car – a larger fuel tank was fitted and the rear seats specially hinged so that the drivers could get in and out, through the boot, while the car was still in motion. At these change over times and when the car needed servicing, it was driven into a mobile servicing bay, a hollow trailer with platforms at either side, which was towed by a modified Morris Oxford. Once in the bay, the oil, water and tyres could be maintained. The rear wheels could even be changed with the car still propelling itself by lifting and braking the wheel to be changed, while still being driven by the other. Early 1953 saw the introduction of the light commercial vehicles. The range comprised of a pick up and a van which were built on a separate chassis.The range was completed in late 1953 with the introduction of the Traveller. Although this was of the same monocoque construction as the saloon it had an exposed, structural ash frame with aluminium panels. A horizontal slat grille was fitted from October 1954, as well as a new dashboard with a central speedometer. 269,838 examples of the Series II had been built when production ended in 1956. Morris Minor Series II 1954 SWK363 SWK 363 is a Morris Minor Series II Model launched for the Oct. 1954 Earls Court Motor Show It's updated Austin-designed 803cc overhead valve A-series engine replacing the original side valve unit. This was the last Morris Minor with a split windscreen and small rear window, But was the first with the new style Horizontal bar radiator grill and new style dashboard, the model ended in 1956 when the Morris 1000 was introduced that lasted until 1972. SWK 363 was first registered in Coventry in May 1956. The car was restored by it’s previous owner in the 1980's and acquired by Maurice Dickens the present owner in June 2011 when only slight work was required to get the car re-commissioned for the road after standing in the previous owners garage for about three years. |

Geoff Norgrove

Rover 8hp 1906

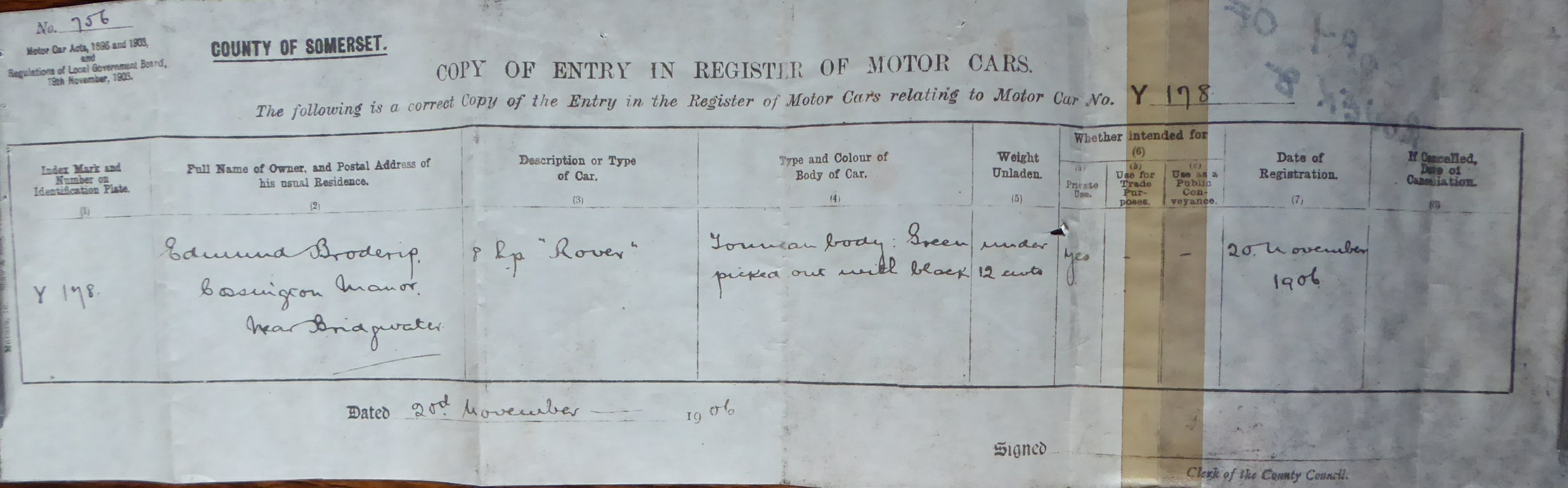

Y178 In 1964 following an advert in the “Farmers Weekley” for parts for my 1913 Rover 12hp known as a Clegg Rover. A reply came from someone in Chepstow saying they knew of a 1904 Rover which was up for grabs and should he contact the now owner. The mans father had kept a garage in Chepstow, he had died and had this Rover the price was £50. Three of us went down to have a look in the 2 ton Lodestar Austin. When we arrived we were confronted with the front half of the car and asked about the rear half. We were told it was in the big hole in the yard underneath a damson tree. A JCB turned up and the tree and then the rear half were lifted out. I paid the money and we departed for home. The above photographs were taken the next morning ,then followed 50 years of intermittent restoration. Rover 8hp

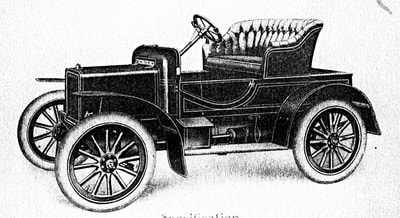

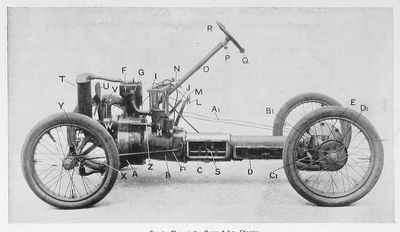

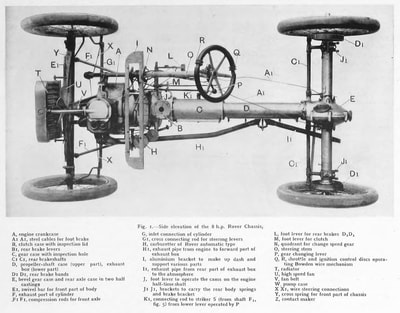

The Rover 8 was a small single-cylinder eight-horsepower 1327 cc car made by the British Rover car company. It was Rover's first production car The car, designed by Edmund Woodward Lewis (1870-1941) who had joined Rover from Daimler, had an unusual structure. Instead of the conventional chassis the car had a backbone formed by the engine crankcase, the gearbox housing, the propeller shaft housing and the rear axle housing, the whole described as having a box girder section. The backbone frame, without bump-compliance at the rear apart from the tyres, was suspended from the front axle at just one point by a pivoted transverse leaf spring which made no contribution to transverse stability and the whole car rested on just three points. The body, through its own sub-frame, was mounted on the rear axle using semi-elliptic springs.

The single-cylinder engine displaced 1327 cc with a bore of 4.5 in (114.3 mm) and stroke of 5 in (127.0 mm). Its inlet and exhaust valves were both mechanically operated.cam profiles Engine braking It had an unusual pedal control that changed over the valve operating cams to provide extra engine braking. When it was wished to slow the engine a driver's foot lever moved the cams first to reduce valve liftand then second, on further pressure, the valves are closed completely and the engine is effectively an air compressor slowing the rear wheels. At the engine's normal speed of 900 rpm it produced eight brake horsepower. If desired the engine could be accelerated up to 1,500 rpm by judicious adjustment of both the throttle and the ignition timing. Above the combustion chamber an aluminium inspection plate may be removed to inspect water jacket spaces for blockage or potential blockage. The crankshaft and camshaft were fitted with large ball races. The sparking plug sits just above the inlet valve. Electric current is provided by an accumulator (battery) and a Bassée-Michel high-speed trembler coil and timed with a wide contact. Wires are able to be kept very short. Should there have been any experience of short circuiting a switch on the steering wheel centre switched off the current without a hand leaving the wheel. A propellor draws water from the base of the radiator pushing it up through the engine's water jackets to the radiator's top tank from where it descends to the base again through twelve copper tubes carrying aluminium gills. A pulley on the end of the crankshaft drives a belt to a fan drawing air through the radiator. The metal to metal type clutch runs in oil. It has an engine driven bell-shaped clutch forced by a coil-spring on the output shaft to engage with a floating cast iron disc which transmits power to the three-speed gearbox. The speeds provided by the gearbox are: 1st: 8 mph 2nd: 16 mph 3rd or top gear: 24 mph reverse: 8 mph Top gear is a direct drive through from the clutch to the rear bevel on the differential within the back axle's aluminium casting. Economical production is provided by making the gearbox from just three sizes of gear wheel. The change speed lever is at the bottom of the steering wheel operated through a concentric tube around the steering column. Steering and suspension The front axle is made from steel tube. Ball cup swivel pins are mounted at each end with a slight set given the wheel axles. A cross rod joins the steering levers on each wheel. The cross rod is linked to the foot of the steering column by double cable which rotates around the steering column. A spring is incorporated in the cable so that only one of the cables is tight. The small diameter of the steering spindle was claimed to obviate road shock. There are compression rods from the gearbox casing to stay each end of the front axle and minimise deflection by road shock. The rear axles are mounted on ball bearings and encased with the differential in one aluminium casting. The bolt which fastens the long semi-elliptical springs which support the back of the body are fastened to the same casing. The differential casing has an inspection cover as does the gearbox and clutch. Lubrication The engine is lubricated by the splash system. During regular maintenance the clutch case, the gearbox case and the rear axles are fed with lubricant through the inspection covers. Brakes The brakes on the back wheels are all wrought iron using malleable iron drums. They are controlled by foot lever operating through compensating wires. Body The two passengers are provided with bucket type seats, the driver's |